In India, a wedding saree is not merely a garment but a living testament to the tradition, the skill & cultural legacy. The allure of Benarasi, Chanderi & Gota Patti sarees lies in their intricate craftsmanship, rooted in centuries-old practices. Each thread, each motif, carries the encrypted history of heritage, making these sarees not just bridal finesse, but heirlooms of immense cultural significance. Let’s embark on a journey through these handcrafted treasures, unraveling their stories, decoding artisan jargon & appreciating the artistry that makes them timeless.

The Benarasi Saree

History & Mythology

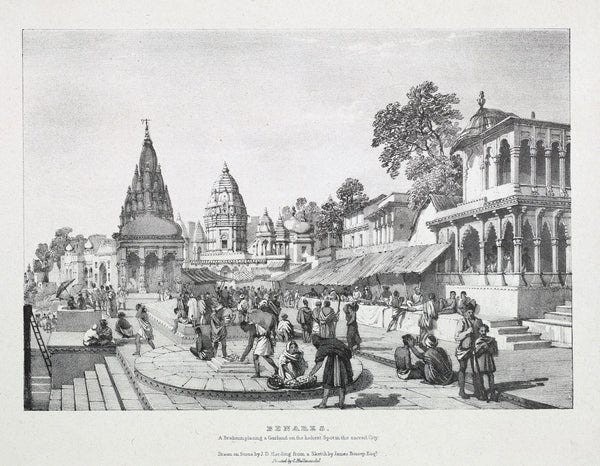

Vedic texts through the ages have mentioned a “Hiranya vastra“— a golden fabric worn by the gods—believed to symbolize the intricacy of Benarasi saree. As early as the 2nd century BC, the sage Patanjali praised “Kasika vastra,” or cloth from Kashi, capturing its superiority over fabric from Mathura.

With roots as ancient as documented in its earliest forms, the Benarasi saree stands as a prominent symbol of India’s craftsmanship & cultural heritage. Its intricate design, combined with remarkable durability, makes it a timeless heirloom. Local lore credits Lord Shiva for blessing the city with this craft, symbolizing purity & prosperity. Over time, Benarasi sarees became a proud emblem embracing royalty, gracing weddings & grand occasions.

Step-by-Step Crafting Process

Creating a Benarasi saree is a meticulous, labor-intensive process that demands precision & expertise:

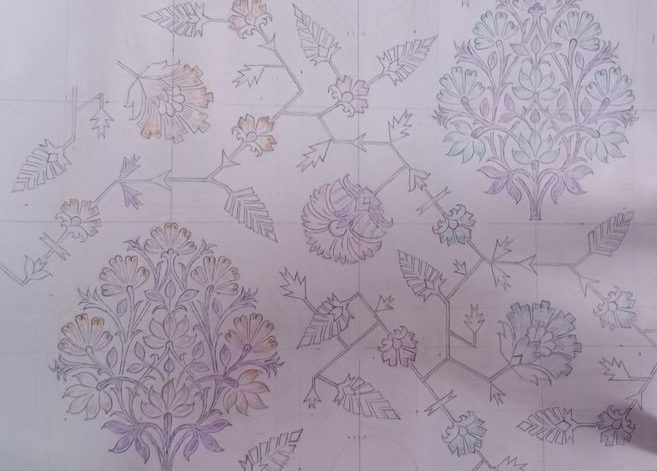

Design Conceptualization: Designing these sarees is a mastery in its own. It starts by drawing the design onto the paper.

Once the design is finalized, it is then drawn on ‘Naksha’ (graph paper). Artisans sketch motifs inspired by Mughal architecture, floral designs & paisley patterns.

Punch Card Preparation: Designs sketched on graph paper dictate the pattern for holes punched into cardboard stencils, known as Jacquard cards or Naksha pattas, which guide the weaving process. Jacquard cards are essential for transferring intricate designs onto fabric.

Each card, punched with precise patterns, guides the weaving of motifs ranging from delicate florals to regal designs. A single Benarasi saree may require thousands of these stencils, with more complex designs demanding a higher number of cards to achieve their intricate detail.

Yarn Selection & Dyeing: Raw yarns are sourced from local markets. These yarns are pure mulberry silk threads that are chosen to be dyed in vibrant eclectic colors.

The dyer then takes a huge container with water & adds dye & brings to a boil. Meanwhile, raw yarn is fixed onto steel rods & dipped repeatedly into boiling water infused with dye.

The process continues until the yarn absorbs the color evenly, ensuring a rich, uniform hue across every strand. Excess water is drained out, followed by stretching them under the sun to dry out the remaining moisture.

Reeling Process: Once the yarns are dyed, these complex hangs of tangled strands are transformed into smooth, single threads.

The reeling machine, which is a huge rotating structure is manually operated where the operator inserts these tangled strands into the machine resulting in smooth, single threads & them wrapped around small reels/cones. These reels are now used for warping & filling shuttle for weft.

Loom Setup: The weaver sets up the warp, also known as “tana” which is the longitudinal thread & weft, also known as “bana” which is the latitudinal thread on the loom, ensuring that the threads are aligned perfectly. The jacquard punch cards are then attached to the loom.

Weaving: Using a traditional handloom, artisans interlace silk & zari threads. The ‘Meenakari’ technique is often employed to add colorful accents to the zari work. It is followed with the back & forth movement of the shuttle as well as carrying out the desired design by interlacing silk & zari threads.

Finishing Touches: After weaving, the saree undergoes a series of finishing processes, including washing, polishing & starching, to enhance its sheen & texture.

Depending on the complexity of the design, a Benarasi saree can take anywhere from 15 days to six months to complete.

The Chanderi Saree

Where Artful Minimalism Meets Tradition

Chanderi sarees, often referred to as “woven air” or (bunni hui hawa), originated in the town of Chanderi in Madhya Pradesh, which became a prominent weaving center by the 11th century. The region’s strategic position on key trade routes connecting Gujarat, Malwa, Mewar & Central India further boosted its prominence. Chanderi is mentioned in both mythological & historical texts, with the Mahabharata linking it to Lord Krishna’s cousin Shishupal & the Maasir-i-Alamgiri noting that Emperor Aurangzeb ordered garments made from gold-embroidered Chanderi for ceremonial robes.

Originally made entirely from 200-count cotton, Chanderi gained its signature cotton-silk blend in the 1940s when Japanese silk yarn was introduced. The fabric was once reserved for royalty, used to create pagdis, sarees & dhotis. In recent years, weavers have begun producing luxurious silk-on-silk Chanderi sarees, further elevating its status as a high-end textile.

Step-by-Step Crafting Process

Chanderi sarees are known for their lightweight, translucent fabric & intricate motifs:

Yarn Preparation: Artisans begin by sourcing the finest cotton & silk yarns, ensuring only the best-quality materials are used. The silk acts as the warp, & the fine cotton is used as the weft which creates the signature light, gossamer texture of the Chanderi saree. For a luxurious finish, Kora silk, the unbleached silk, is often chosen to maintain the delicate sheen of the fabric.

Dyeing: Traditionally, Chanderi sarees were made in white, but over time, artisans introduced subtle hues using natural dyes, creating a soft & ethereal color palette. Pastel shades still dominate, incorporating gold tones to reflect Chanderi’s elegant aesthetic. One of the popular variations, known as the ‘Ganga-Jamuna,’ features a body in light color with contrasting borders that shimmer in different light, depicting the interplay of colors.

Warping: Once dyed, the threads are stretched onto the loom, known locally as “tana-bana tayyar karna”. The cotton & silk threads are carefully prepared, ensuring they are ready for the weaving process. This step is crucial for maintaining the tension & consistency of the fabric.

Weaving: It’s quintessential to know that every single loom-producing Chanderi is a handloom. The weaving takes place on a traditional pit loom, where the magic of Chanderi comes to life. Artisans interlace the silk warp & cotton weft with precision, creating a sheer, fine texture.

The intricate motifs, known as Buttis, are woven using the ‘extra weft’ technique, where additional threads are inserted to form designs. The Buttis often take inspiration from nature, such as lotus bud or jasmine flower, & are embroidered using a separate needle for each motif.

The most popular design is the Ashrafi Buti, which features gold & silver motifs across the canvas. The saree’s Patti woven border is a distinctive feature, where thicker silk threads are used to create a bold, defined border, accentuating the fine weave of the body.

Finishing: Once woven, the saree undergoes washing, starching, & pressing to enhance its texture & sheen, giving it a crisp, smooth finish.

An interesting aspect of Chanderi’s weaving process is the use of wild onions, found abundantly in the region, for starching the cotton. Unlike other weaving communities that use rice starch, this local plant, which grows surplus, contributes to the sustainability of the craft.

A Chanderi saree typically takes 10 to 20 days to complete, depending on the intricacy of the design & motifs.

Gota Patti Saree

History & Mythology

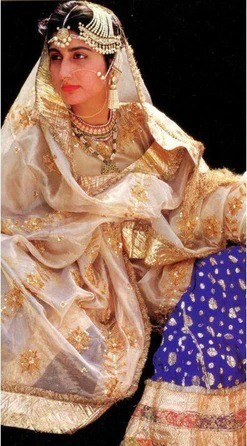

Gota patti, also known as Aari Tari, zardozi, or Lappe ka Kaam, is often associated with Rajasthan, particularly cities like Jaipur, Ajmer, Kota, Udaipur, & Bikaner, which are considered the main hubs for this intricate craft. However, some trace its origins to Punjab in Pakistan before it spread across India. Dating back to the 3rd to 5th centuries, this centuries-old technique was initially used by royal families & court members. Gota patti is a form of appliqué embroidery, traditionally done with gold & silver threads, making it a luxurious & expensive craft. It was used to embellish garments for royalty, priests, temple idols, & even altars, highlighting its cultural significance in royal & religious ceremonies.

Step-by-Step Crafting Process

Gota Patti work is a labour-intensive art that involves precision & creativity:

Fabric Selection: The journey begins with the careful selection of lightweight, ethereal fabrics like chiffon, georgette, crepes & tussar silks— chosen for their delicate texture that perfectly complements the opulence of the gold & silver ribbons. These fabrics create the ideal canvas for the intricate designs to unfold.

Design Tracing: Artisans start by sketching motifs onto tracing paper & make precise perforations to transfer the design onto the fabric. The fabric is then anchored on a wooden frame, known locally as “Adda”, where the design is outlined with chalk, ensuring that every curve & edge are perfectly aligned before the embroidery begins.

Gota Cutting: The craft’s signature element—narrow strips of gota—are cut into precise shapes, ranging from delicate flowers to ornate leaves (patti) & geometric motifs. These shimmering metallic ribbons are carefully measured & shaped to make each design alive.

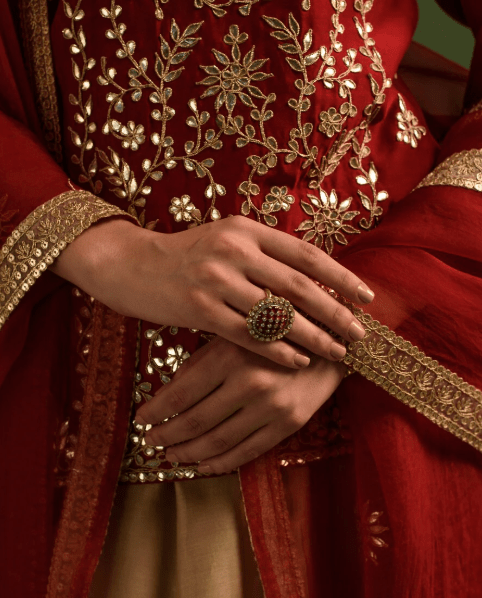

Applique Work: Using the hand applique technique, artisans sew the cut gota pieces onto the fabric. Each piece is carefully stitched into place using a needle & thread to form intricate patterns, which includes popular motifs like peacocks, paisleys & floral designs.

Embellishment: The finishing touch lies in the addition of sequins, beads & mirrors, which illuminate the fabric with a radiant, reflective glow. These embellishments enhance the design, bringing an extra layer of glamour and sophistication to the saree.

Finishing: Once the embellishment is complete, the saree undergoes steaming & pressing, setting the gota work in place & giving the fabric a polished, luxurious finish.

Crafting a Gota Patti saree can take anywhere from 10 days to a month, depending on the complexity of the design.

Challenges Faced by Artisans

The making of a handcrafted saree is a labor-intensive process that demands precision, patience & skill, but artisans face numerous challenges. The influx of machine-made replicas & rising costs of raw materials makes it difficult to sustain traditional handloom weaving. The process itself is laborious, often taking weeks, while artisans struggle with low wages & limited market access, relying on middlemen. Additionally, younger generations are moving away from the craft due to financial instability, threatening its survival. Despite these hurdles, initiatives supporting handcrafted textiles are helping preserve this rich cultural legacy.

At Jaypore, we take immense pride in celebrating India’s rich textile heritage & the skilled artisans behind it. By offering a platform for handcrafted treasures, we bring traditional crafts into the spotlight, ensuring they receive the recognition they truly deserve. Our commitment goes beyond just selling products—it’s about preserving centuries-old craftsmanship & providing a sustainable livelihood for artisans across the country.

When you choose a handwoven saree from us for your wedding, you’re not just selecting attire—you’re weaving tradition into your special day. At Jaypore, each saree carries the legacy of generations, celebrating craftsmanship that mirrors the beauty & significance of Indian weddings. By wearing a handcrafted piece, you honor the artisans’ dedication, support their livelihood & add a touch of timeless heritage to your ceremony.

Leave a comment