Once upon a winter, a little sheep spun magic into wool— a fiber so wondrous, it carried the whispers of nature. Soft yet strong, naturally insulating and breathable, wool became the perfect answer to winter’s crisp chill— a gift from nature to wrap us in warmth.

Nestled amidst the snow-clad Himalayas, Kashmir exudes an aura of mystique, beauty & cultural richness. Among its myriad treasures, the Kashmiri Pashmina stands as a testament to unmatched craftsmanship, embodying centuries of tradition, luxury & elegance.

Derived from the Persian word ‘Pashm’, meaning wool & often dubbed as “soft gold,” Pashmina isn’t merely a fabric—it’s a legacy carried forward by artisans who breathe life into its intricate threads.

Let’s unravel the captivating journey of this iconic winter craft, from its mythological origins to the hands that meticulously craft each of these masterpieces. Its story begins not just with the Changthangi goats but also with the artisans who, over centuries, have transformed this raw treasure into wearable masterpieces that exude slow-crafted luxury & warmth.

A Historical Perspective

The history of Pashmina is as rich & layered as the fabric itself. Tracing its origins back to ancient India, where sheep rearing, spinning & weaving of wool was mentioned in the parts of ‘Arya Life’, where wool held ceremonial purity & was often used as ‘Asan’, a rug used in religious practices. It is even said that the weaving & spinning of wool were blessings bestowed by ‘God Pasham’, the deity of shepherds.

The Indus Valley Civilization reveals early evidence of wool craftsmanship & by the 1st century CE, Kashmiri Pashmina had found its way to Roman courts, celebrated as an opulent gift. However, it was in the 15th century, under the patronage of Emperor Zain-ul-Abidin, that Kashmiri Pashmina rose to prominence. Encouraging weavers to innovate, the emperor laid the foundation for a thriving industry that would later captivate the Mughal courts.

By the 16th century, the Mughal kings adorned themselves with Pashmina as a symbol of prestige. Emperor Akbar famously gifted Pashmina shawls as khilats (robes of honor), further cementing their status as an aristocratic treasure.

The 18th century saw Pashmina crossing continents, reaching the European elite groups. Napoleon Bonaparte gifted an orange-hued Pashmina to his wife, Empress Joséphine, who became an ardent admirer, owning 300-400 shawls. The fabric soon graced French fashion magazines & became a coveted symbol of elegance across Europe.

The Making of Pashmina

Pashmina originates from the high-altitude Changthang plateau in Ladakh, a region so barren & cold that nature itself has gifted its inhabitants—the Changra goats—with a fleece so fine & warm that it defies the environmental elements.

This is no ordinary wool; it is a rare treasure that travels hundreds of miles & undergoes an intricate transformation to become the ethereal fabric cherished by royalty & connoisseurs alike.

Let’s delve into the detailed journey of the making of Pashmina, from the rugged Himalayan pastures to the delicate hands of artisans who breathe life into its fibers.

Harvesting the Precious Fleece

The process begins in the high-altitude regions of Ladakh & Tibet, where the Changra goats, also known as Capra hircus, live at altitudes above 5,000 meters. In these arid, cold climates, nature has blessed these goats with a fine undercoat layer of fleece that grows under the thick outside fur to protect them from temperatures that drop below -40°C.

As spring approaches, the goats naturally shed this undercoat, which is carefully combed out by shepherds. The process is entirely humane, involving no harm or mechanical shearing, which could damage the fine delicate fibers. Each goat produces around 300 grams of usable wool annually, making it a highly precious resource.

Combing

Unlike lamb’s wool that involves shearing, Cashmere is delicately combed from the goat’s undercoat.

Timing is key in this process. As the spring approaches, skilled labors patiently wait for the fleece to naturally loosen, ensuring it comes away effortlessly. Observing the goats closely, they look for signs like rubbing against bushes or fences, indicating the fibers are ready. The fleece is then collected in zip-lock bags labeled with each goat’s name to preserve even the tiniest samples.

Combing begins with the prime areas—ears, neck & chest—where the fibers are softest, before moving to coarser sections like britches. To maintain purity, each section is stored separately in paper bags marked by body area, capturing the essence of this meticulous tradition.

Sorting & Cleaning

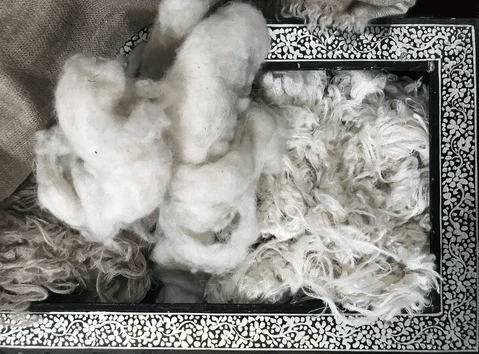

Upon arrival in Kashmir, the raw wool undergoes a meticulous sorting process by skilled women artisans. This is a crucial & respected role that exists only in Kashmir. The fleece is carefully examined to remove impurities & any remaining coarse fibers.

This step ensures only the softest & finest wool is used. This raw material, bundled & unkempt, is transported across the formidable Himalayan passes to the lush valleys of Kashmir. Here, the magic truly begins as artisans weave the wool warmth into cozy comfort layers of warmth.

Carding

The sorted wool is then carded—a process where the fibers are brushed & aligned to make them smooth & ready for spinning.

This step transforms the wool into fluffy, soft balls, setting the stage for the spinning process.

Hand-Spinning the Yarn

Spinning is an art, practiced exclusively by women in Kashmir on a traditional hand-operated charkha (spinning wheel). The aim is to create an impossibly fine, gossamer-like yarn, a task that requires extraordinary patience & skill.

First, the fleece undergoes a meticulous sorting process to remove any remaining impurities. Each thread is spun with care, ensuring it remains unbroken—a feat achievable only by hand.

Bringing Threads to Life

Weaving Pashmina is a task reserved for master craftsmen, often men, who use hand-operated wooden looms to create the fabric.

The loom made of locally sourced wood, is set up according to the design requirements. The resulting fabric can be left plain, dyed in vibrant colors, or embroidered with breathtaking artistry.

Winding the Warp

The creation of a Pashmina warp starts with an age-old process called ‘Yarun’ in Kashmir. Here, skilled artisans manually wind fine Pashmina yarn across 4 to 8 iron rods placed on the ground.

To craft a warp extending 10 meters, approximately 1,200 threads are evenly stretched, requiring the artisan to walk a staggering 12 kilometers around the rods which is a true testament to patience & dedication.

Dressing the Warp

Before the warp can be fixed on the handloom, it undergoes Bharun, a process carried out by the Bharangur or warp-dresser.

This delicate step involves stretching & securing the yarn onto the heddles of a traditional loom, known as saaz. This intricate preparation ensures the threads are perfectly aligned, laying the foundation for the weaving process.

Winding the Yarn

Finally, the slightly stretchy yarn, once dried in the sun, is rewound onto wooden spindles called prech— a process referred to as Tulun in Kashmir.

With one hand the spinner holds the spun yarn & turns the prech to give a slight twist to enhance its strength. The final yarn, now in hanks is the next step that transforms the yarn into a ready-to-weave state, bringing it one step closer to becoming an exquisite Pashmina art.

Dyeing: A Play of Colors

Depending on the design, weavers may use multiple shuttles, carefully passing the weft through the warp to create patterns. The fabric can be left in its natural ivory or light brown shades (the color of Changra goats), dyed plain, or further embellished with intricate embroidery.

Artisans use natural or synthetic dyes, preparing the colors in copper vessels heated over wood fires.

The hanks of yarn are carefully submerged & monitored to ensure even absorption of color. This step is as much an art as a science, with artisans checking & re-checking the yarn until it achieves the desired hue.

Setting the Loom

The loom, handcrafted from local wood, is prepared according to the design requirements. Each warp & weft thread is positioned with precision to ensure the pattern emerges flawlessly during the weaving.

Preparing the Warp & Weft

Before weaving, the warp (longitudinal threads) is stretched out & coated with a rice-water paste to strengthen the threads. This coating is washed off after weaving to restore the supple softness of the fabric.

The weft (horizontal threads) is made of fine Pashmina yarn & is passed through the warp using shuttles made of Mulberry wood.

Embroidery is where the true artistry of Pashmina shines. This final step elevates the fabric from a mere textile to a masterpiece of craftsmanship.

Creating Patterns

The process begins with artisans using hand-carved walnut wood blocks to stamp patterns onto the fabric.

These blocks are dipped in a rice-and-gum paste & pressed onto the fabric. The stamped patterns guide the embroiderers, & the paste is washed off after completion.

Types of Embroidery

Ari Embroidery

With its roots deep in Kashmiri tradition, Ari embroidery transforms fabric into a canvas of alluring beauty by using a unique hook needle, known as an ‘ari‘.

Artisans create striking patterns adorning vivid blossoms, almond clusters & intricate shapes, perfectly embodying Kashmir’s artistic soul. While machine versions exist, the charm of hand-embroidered Ari lies in its painstaking detail & masterful artistry.

Kani Weaving

Every Kani shawl is a poetic fusion of tradition & precise dexterity & 3-4 years to craft.

The artistry lies in the use of ‘kanis,’ small wooden sticks pointed at each end around with various colors that are used to create intricate patterns that are woven in very fine twill weaving technique.

‘Talim’ is a coded pattern through which the designs are made. The beauty of these codes is that only the weavers can interpret.

The next step is followed by making the warp. Colorful bobbins are meticulously arranged to match the design, guided by the talim. When a new color is needed, two bobbins are seamlessly joined, continuing the rhythmic process until the shawl is complete.

Sozni Embroidery

Depending upon the intricacy, a single Sozni shawl can take 2-3 artisans upto a year to complete it. Paisley, florals reflect Kashmir’s cultural richness, making each shawl a true labor of love & artistry.

The journey of Sozni embroidery begins with intricate designs sketched on paper & engraved onto walnut wood blocks.

These blocks are used to hand-print the patterns onto Pashmina fabric with removable ink, creating a guide for the embroidery.

With a fine needle in hand, artisans bring the design to life, crafting delicate stitches that mirror the front on the reverse side. This signature double-sided detailing is achieved through a precise looping technique, reflecting the unmatched craftsmanship of Sozni embroidery.

Finishing Touches

Once woven & embroidered, the shawls undergo a series of finishing processes. The patterned traces on these shawls are thoroughly washed in the rivers flowing down from the high mountains.

The natural minerals flowing in this cold water contribute to the lustrous shine on these shawls. These are stretched to dry out the weave & using mechanical rollers to steam press & iron to enhance its sheen & softness. These final steps ensure the shawl meets the highest standards of quality & luxury.

The Time It Takes

A single Pashmina shawl can take anywhere from 3 to 18 months to complete, depending on its complexity. From harvesting the wool to the final embroidery, each stage involves countless hours of dedicated effort.

Every Pashmina shawl is a labor of love, reflecting the dedication & artistry of countless individuals. From the high-altitude herders in Ladakh to the skilled artisans of Kashmir, each hand that touches the fabric contributes to its unparalleled beauty. Owning a Kashmiri Pashmina is not merely a luxury; it is an appreciation of a culturally rich heritage that has stood the test of time, connecting us to the timeless traditions of the Himalayan region.

Jaypore serves as an ingenious platform to showcase & celebrate the rich tradition of Indian craftsmanship, including the exquisite artistry of Pashmina shawls. We emphasize the value of preserving India’s cultural heritage while offering a space where traditional craftsmanship meets contemporary flair. The unmatched skill & dedication behind every handcrafted Pashmina comes to life with those who appreciate its unique legacy.

Leave a comment