It takes three seconds to scroll past it on Instagram.

It takes days of devotion to create it.

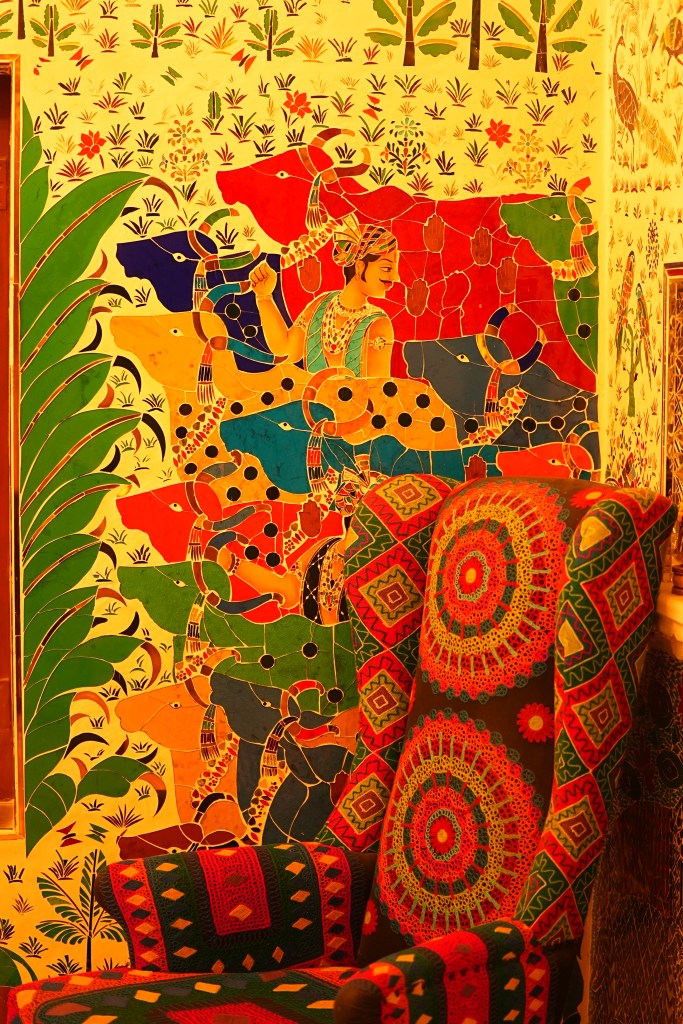

Somewhere in Kutch, Jaipur, or Varanasi, long before it appears in a perfectly filtered square on your feed, a handcrafted piece begins its journey in silence. There are no hashtags in the workshop. No trending audio. Just the steady rhythm of human hands at work.

Table Of Content

- Hour 1 to 3: Before the First Post, There Is Preparation

- Hour 4 to 10: The Rhythm Sets In

- Hour 11 to 24: Detail That Cameras Cannot Capture

- Hour 25 to 40: Refinement Over Rush

- The Final Hours: From Workshop to Feed

Hour 1 to 3: Before the First Post, There Is Preparation

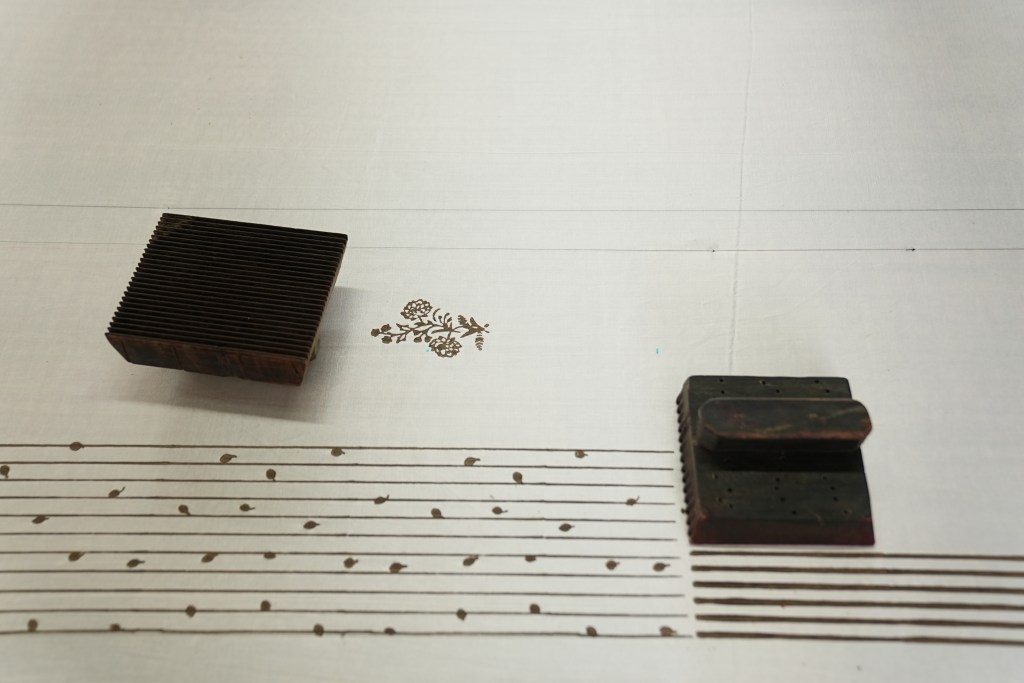

While most of us are replying to emails or clearing morning notifications, the artisan is already preparing the canvas. If it is handloom weaving, threads are stretched carefully across the loom. If it is block printing, fabric is washed, sun dried, and smoothed. Every inch is inspected. A single knot in yarn or uneven tension can disrupt the entire pattern.

The process is slow and intentional. Organisations like Khadi and Village Industries Commission have long emphasized that hand production cannot be hurried without losing integrity. The artisan knows this instinctively.

Consider the making of a Banarasi sari. The legendary Varanasi brocades once patronised by Mughal courts can take weeks, sometimes months, to complete depending on the intricacy of zari work. Each motif is counted, not printed. Each thread is placed with mathematical precision. There is no rushing this stage. The foundation decides everything.

Hour 4 to 10: The Rhythm Sets In

By the time you have scrolled through dozens of posts, the artisan has repeated the same motion hundreds of times. The shuttle moves back and forth on the loom. The carved wooden block is dipped into natural dye and pressed firmly onto fabric. Each press must align perfectly with the last. One slip and the entire length of cloth is compromised. Think of the iconic Bandhani from Kutch.

A single dupatta can contain thousands of tiny hand tied knots. Each dot you see is individually pinched and tied before dyeing. Untying them later reveals patterns that look digitally precise, but are entirely handcrafted. The work demands focus that modern life rarely asks of us anymore. There are no notifications interrupting the rhythm. Only the soft thud of block on fabric. The click of wood against wood. The whisper of thread tightening into place. This is where muscle memory meets mastery.

Hour 11 to 24: Detail That Cameras Cannot Capture

By now, the piece has begun to take form. But what you see in a product reel is only the surface.

Loose threads are trimmed. Motifs are sharpened. Edges are reinforced. If it is embroidery, each stitch is placed deliberately so the tension holds. In Chikankari from Lucknow, as many as thirty different stitches may be used in a single garment. The finesse lies in making the needlework look almost weightless. Major institutions work closely with artisan clusters to preserve these skills because they recognize something important. This is not just production. It is knowledge carried through generations.

Fatigue sets in. Fingers ache. Eyes strain. Still, the artisan continues.

Hour 25 to 40: Refinement Over Rush

In a world obsessed with speed, refinement feels almost rebellious.

The fabric is checked again under natural light. A woven sari is examined for irregularities. A carved wooden piece from Jaipur is sanded until it feels smooth against the palm. A brass diya from Moradabad is polished until it reflects light evenly. No algorithm rewards this patience. No viral moment captures it. Yet this is where the real value is created.

The Final Hours: From Workshop to Feed

Finally, the piece is complete. It is folded, packed, photographed, styled. Perhaps it is placed against a neutral backdrop, paired with soft music, uploaded with a thoughtful caption.

And then it enters the endless scroll. Three seconds. A double tap. Maybe a save.

Those 40 hours become 3 hours of preparing the loom in Varanasi, where warp threads are stretched and aligned by hand. They become 8 hours of steady weaving, the shuttle moving back and forth thousands of times to build strength into cloth. They become long stretches of motif work, where extra threads are inserted one by one to create patterns rooted in centuries of tradition.

But those 40 hours also hold the lives we rarely name. The cotton farmer who waited for the right rain. The spinner at the charkha. The dyer, the washerman, the presser, the packer. They hold knowledge preserved across generations and supported by institutions that work to keep craft alive. What looks like one garment is, in truth, an ecosystem of hands and histories. 40 hours seem small when seen as a number. They become vast when seen as time, dignity, and human effort woven together, hour by hour.

At Jaypore, these hours are not hidden behind trends. They are celebrated. Each piece is a reminder that craftsmanship cannot be compressed into content. It is built slowly, hour by hour, hand by hand. So the next time you pause mid scroll and linger just a little longer, remember this. What feels like an instant of inspiration on your screen may have taken days, sometimes generations, to come alive.

Leave a comment